Services

Our Services

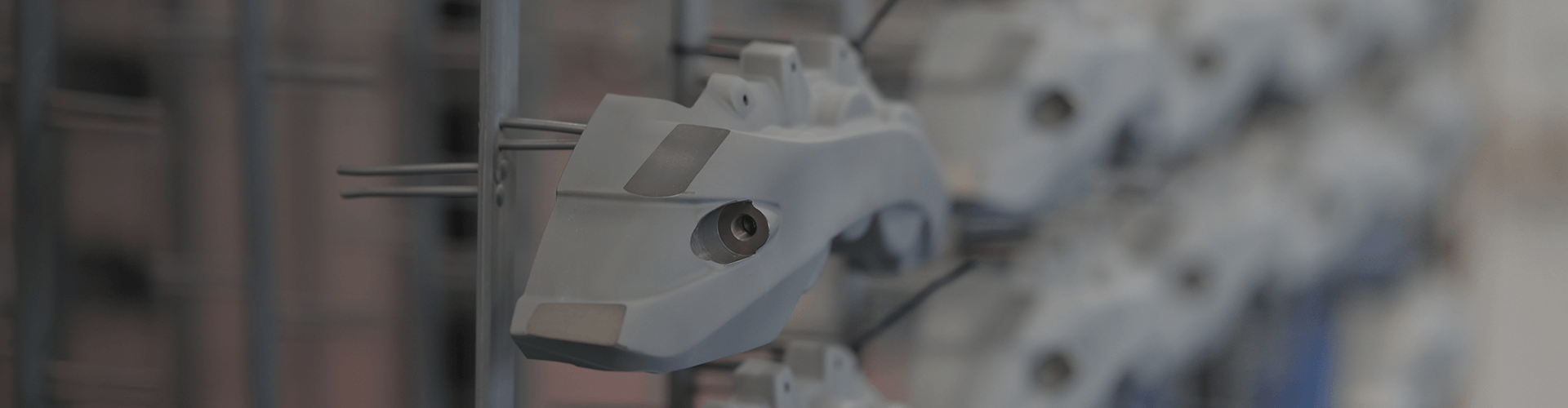

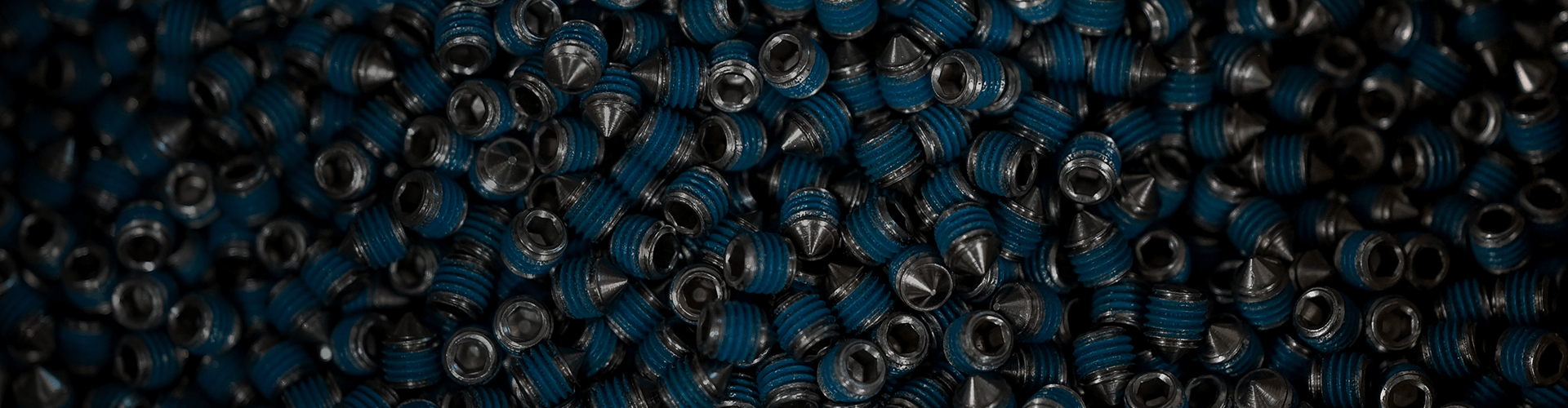

Few job-coaters can match Anochrome Group’s vast range of services and processes. The combined power of our six unique companies means we are able to offer our customers the most appropriate and cost-effective solution to provide robust corrosion protection.

Whether you require a coating to meet a particular specification – or you need the help of our experts to choose the best process – Anochrome stands ready to help with all your needs.

We have been offering some services such as rack plating and barrel zinc electroplating – capable of processing millions of parts a week – for more than half a century.

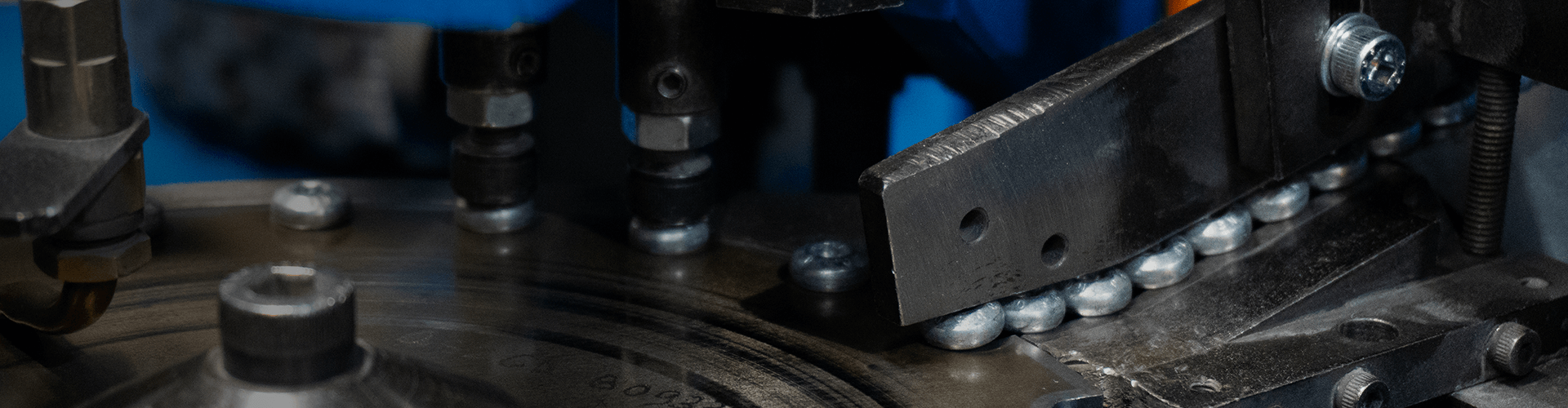

Other processes such as mechanical plating or thermal diffusion are more specialist and are applied in smaller volumes – but come with unique benefits for specific environments.

Speak to our team today to determine the best solution for your needs.

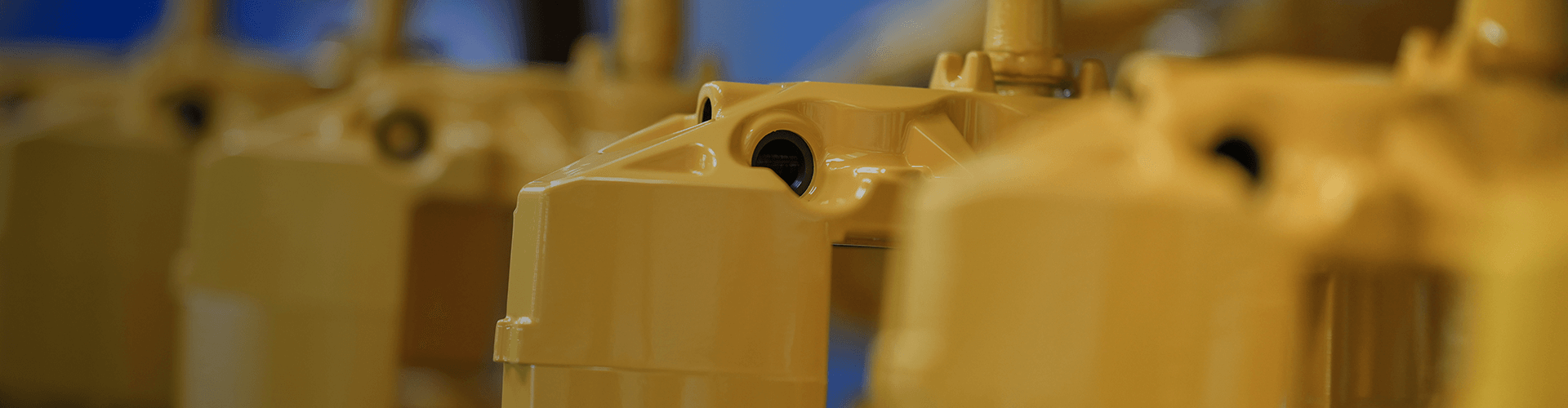

Decorative Coatings

High-performance decorative coatings enhance appearance, durability, and component protection.

Induction Hardening

Strengthens fastener threads precisely, improving wear resistance without distorting surrounding metal areas.

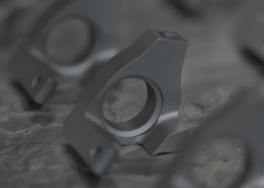

Mechanical Plating

Mechanical plating improves corrosion resistance without hydrogen embrittlement risk.

Thread Protection & Masking

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

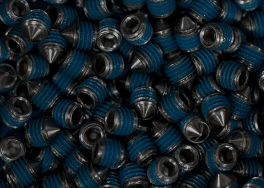

Wax Based Thread Lubricants

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Why Choose Anochrome?

We’ve spent eight decades perfecting our craft and developing the range of services we offer our discerning customers.

Whereas most job-coaters offer just one or two processes, we are proud to specialise in the widest range of technologies, with a solution for almost any requirement.

We achieve this by harnessing the capabilities of our six companies. While each operates individually with their own specialisms, they retain the ability to collaborate achieve any coating goal.

Widest Range of Services

From anodising to decorative coatings, phosphating to thermal diffusion, we’re proud to offer an extensive suite of services for almost every requirement.

The Power of Six

The six businesses within the Anochrome Group all boast different specialities and processing machinery – supporting the widest range of sectors.

Always Honest Advice

We have hundreds of years of experience and knowledge within our ranks – and we pride ourselves on providing honest advice on the most effective route forward.

Licence to Thrill

We hold numerous licences that give us authorisation to apply some of the most innovative and in-demand coatings to parts of all shapes and sizes.