Unplanned maintenance, premature asset replacement and operational downtime caused by corrosion remain some of the most costly challenges facing multiple sectors – but better understanding of ISO 12944 can significantly reduce that risk.

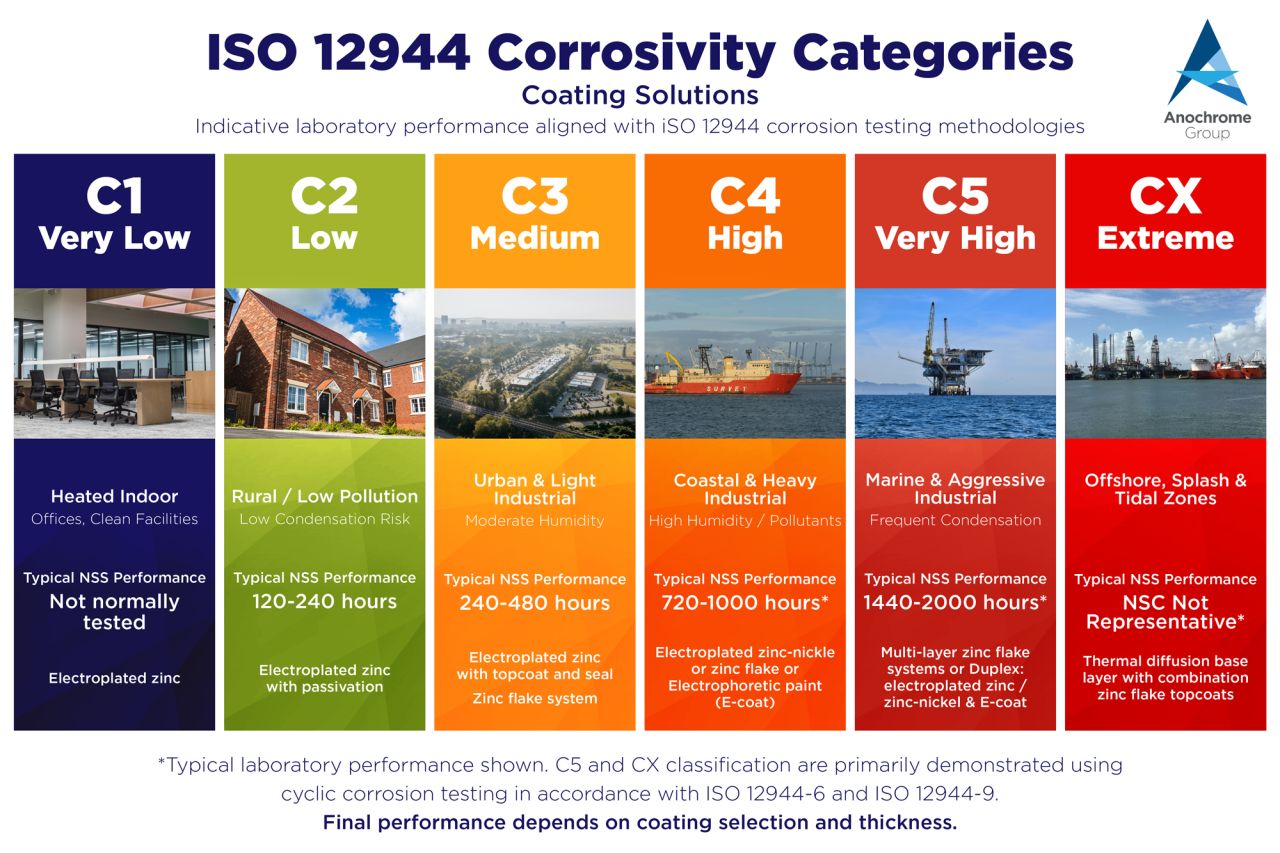

The international standard classifies atmospheric environments based on their corrosivity, ranging from C1 Very Low through to CX Extreme, and outlines durability classifications along with the testing methods used to evaluate coating performance.

Steve Norman, Commercial Director at Anochrome Group, said ISO 12944 has been effective in enabling engineers and specifiers to match protective systems to real world exposure conditions.

“A system based approach that considers environment classification, coating chemistry, application method, thickness and test validation allows organisations to balance durability, cost and long-term performance,” he said.

“This is particularly relevant across sectors such as rail, renewables, oil and gas, petrochemical and the nuclear industry, where components may be exposed to a wide range of aggressive environments over extended service life.”

In lower corrosivity environments, typically classified as C1 or C2, electroplated zinc systems with appropriate passivation are often sufficient to provide reliable corrosion protection.

As exposure levels increase in urban, industrial and coastal locations classified as C3 and C4, more robust solutions are required. These may include electroplated zinc with topcoats and seals, zinc flake systems, zinc nickel alloys or electrophoretic paint systems to enhance barrier protection and resistance to corrosive agents.

For Very High and Extreme environments classified as C5 and CX, corrosion protection strategies become increasingly complex. These environments are common in marine, offshore and heavy industrial applications where high humidity, salt exposure and cyclic wetting conditions are present.

In such cases, multiple layer zinc flake systems, duplex combinations of metallic coatings with organic topcoats and thermal diffusion base layers are frequently required.

Steve added: “As infrastructure continues to expand into increasingly demanding environments, particularly within offshore renewables and energy transition projects, informed coating selection in accordance with ISO 12944 remains a critical element of sustainable asset protection.

“The cost of corrosion related failure can be significant with the risk of unplanned maintenance, asset replacement and operational downtime.

“Anochrome’s team of vastly experienced and knowledgeable technicians can help choose the right application and the right process for every requirement, eliminating any doubt.”